Most Popular Products

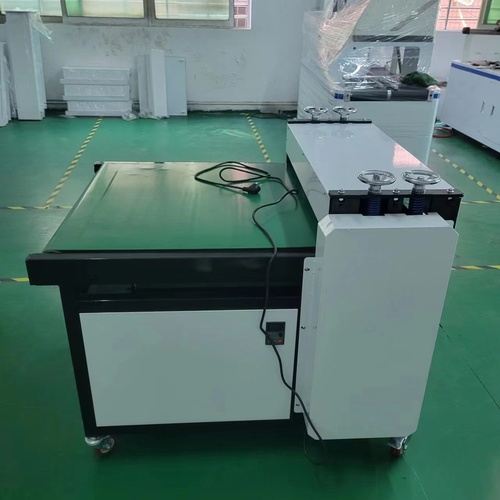

Roller Pressing Machine

Price 130000 INR/ Piece

MOQ : 1 Unit

Roller Pressing Machine Specification

- Country Of Origin

- India

- Accuracy

- 0.05mm mm

- Control System

- Semi-Automatic

- Voltage

- 220V AC Volt (v)

- Frequency

- 50 Hertz (HZ)

- Cooling System

- Air Cooling

- Product Type

- Milling Machine

- Power Source

- Electricity

- Operating Type

- Semi Automatic

- Surface Treatment

- Painted

- Weight (kg)

- 110 Kilograms (kg)

- Warranty

- 01 Year

- Usage & Applications

- Industrial

About Roller Pressing Machine

Main features of High Quality Manual Roller Paper Pressing Machine.

High Quality Manual Roller Paper Pressing Machine:

This pressing machine is mainly used for thin paper, leather,

corrugated cardboard flatten dafter the glue had special equipment.

Type - pressing machine

Production Capacity - 0-35m/min

Max. workable width - 700mm

Weight - 110 kg

Voltage - 220V

Warranty - 1 Year

Precision and Reliability

Engineered for demanding industrial workflows, the Roller Pressing Machine boasts 0.05mm accuracy, delivering exceptional performance with every cycle. Its semi-automatic control ensures user-friendly operation without compromising on output quality or consistency.

Efficient Operation and Safety

Operating at 220V AC and 50Hz frequency, this machine is powered by electricity and features an air cooling system that prevents overheating. The painted surface provides resistance against corrosion, ensuring safe, long-term use even in rigorous working environments.

FAQ's of Roller Pressing Machine:

Q: How does the Roller Pressing Machine achieve such high accuracy?

A: The machine is engineered with precision components and calibrated for an accuracy of 0.05mm. This level of precision is maintained by its robust construction and semi-automatic control system, minimizing human error during operation.Q: What are the primary applications for this roller pressing machine?

A: It is widely used in various industrial sectors that require uniform pressing, forming, or flattening operations, such as metalworking, textiles, and manufacturing. Its precision makes it suitable for tasks demanding high-quality surface finishes and exact dimensions.Q: When is routine maintenance recommended for optimal performance?

A: Basic periodic maintenance, including cleaning the painted surfaces, checking mechanical parts, and ensuring the air cooling system is unobstructed, is advised every few months or after continuous operation. Detailed intervals can depend on specific usage and workload.Q: Where is this machine typically installed in an industrial setup?

A: Due to its moderate weight and electric power source, the Roller Pressing Machine can be integrated into production lines, workshops, or standalone workstations, depending on workflow requirements. It is suitable for small and large factories alike.Q: What benefits does the semi-automatic operating type provide?

A: Semi-automatic controls streamline operation, reducing manual input and improving consistency. This not only increases productivity but also minimizes errors and operator fatigue, ensuring stable output quality over extended use.Q: How does the air cooling system enhance the machine's longevity?

A: The air cooling system effectively dissipates heat generated during operation, preventing overheating and associated wear on components. This extends the machine's service life and maintains high performance levels even during prolonged usage.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

|

OM VIR PRINT O PACK

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry